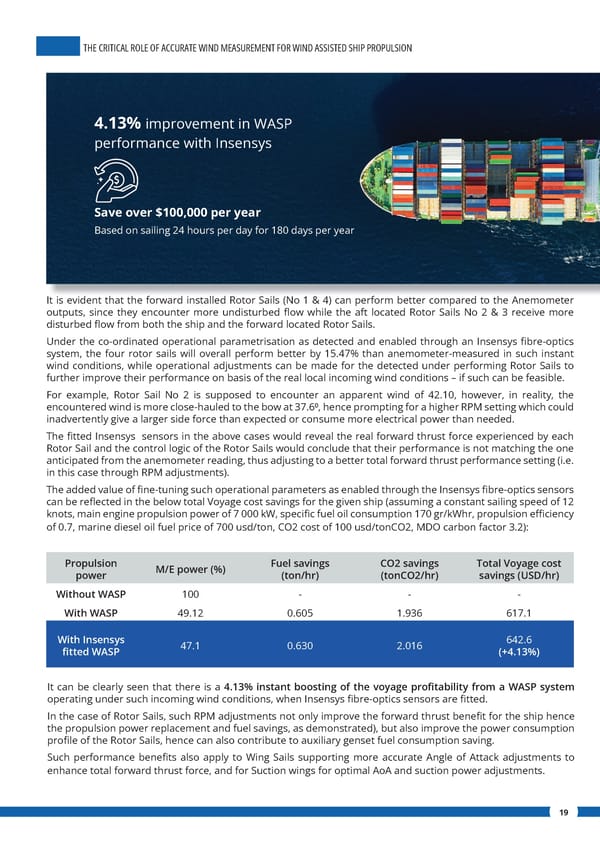

THE CRITICAL ROLE OF ACCURATE WIND MEASUREMENT FOR WIND ASSISTED SHIP PROPULSION 4.13% improvement in WASP performance with Insensys Save over $100,000 per year Based on sailing 24 hours per day for 180 days per year It is evident that the forward installed Rotor Sails (No 1 & 4) can perform better compared to the Anemometer outputs, since they encounter more undisturbed 昀氀ow while the aft located Rotor Sails No 2 & 3 receive more disturbed 昀氀ow from both the ship and the forward located Rotor Sails. Under the co-ordinated operational parametrisation as detected and enabled through an Insensys 昀椀bre-optics system, the four rotor sails will overall perform better by 15.47% than anemometer-measured in such instant wind conditions, while operational adjustments can be made for the detected under performing Rotor Sails to further improve their performance on basis of the real local incoming wind conditions – if such can be feasible. For example, Rotor Sail No 2 is supposed to encounter an apparent wind of 42.10, however, in reality, the encountered wind is more close-hauled to the bow at 37.60, hence prompting for a higher RPM setting which could inadvertently give a larger side force than expected or consume more electrical power than needed. The 昀椀tted Insensys sensors in the above cases would reveal the real forward thrust force experienced by each Rotor Sail and the control logic of the Rotor Sails would conclude that their performance is not matching the one anticipated from the anemometer reading, thus adjusting to a better total forward thrust performance setting (i.e. in this case through RPM adjustments). The added value of 昀椀ne-tuning such operational parameters as enabled through the Insensys 昀椀bre-optics sensors can be re昀氀ected in the below total Voyage cost savings for the given ship (assuming a constant sailing speed of 12 knots, main engine propulsion power of 7 000 kW, speci昀椀c fuel oil consumption 170 gr/kWhr, propulsion e昀케ciency of 0.7, marine diesel oil fuel price of 700 usd/ton, CO2 cost of 100 usd/tonCO2, MDO carbon factor 3.2): Propulsion M/E power (%) Fuel savings CO2 savings Total Voyage cost power (ton/hr) (tonCO2/hr) savings (USD/hr) Without WASP 100 - - - With WASP 49.12 0.605 1.936 617.1 With Insensys 642.6 昀椀tted WASP 47.1 0.630 2.016 (+4.13%) It can be clearly seen that there is a 4.13% instant boosting of the voyage pro昀椀tability from a WASP system operating under such incoming wind conditions, when Insensys 昀椀bre-optics sensors are 昀椀tted. In the case of Rotor Sails, such RPM adjustments not only improve the forward thrust bene昀椀t for the ship hence the propulsion power replacement and fuel savings, as demonstrated), but also improve the power consumption pro昀椀le of the Rotor Sails, hence can also contribute to auxiliary genset fuel consumption saving. Such performance bene昀椀ts also apply to Wing Sails supporting more accurate Angle of Attack adjustments to enhance total forward thrust force, and for Suction wings for optimal AoA and suction power adjustments. 19

The Critical Role of Accurate Wind Measurement for Wind Assisted Ship Propulsion Page 18 Page 20

The Critical Role of Accurate Wind Measurement for Wind Assisted Ship Propulsion Page 18 Page 20